Semi-automatic and automatic label applicators

Together with our partners IMA and Herma we supply numerous labeling solutions, ranging from simple manual label dispensers to high-tech customized labeling machines.

Universal to all our labeling solutions is that we offer industrial labeling machines whose powerful functions and high labeling accuracy promote significant savings in production. Further, all labeling systems available through PPS can be delivered to comply with pharmaceutical standards.

We supply labeling solutions ranging from simple label dispensers and semi-automatic labeling machines to automatic label applicators. The machine showcase below is a selection of available labeling machines. Contact us directly for more solutions.

IMA MODULA Syringe assembly machine

The assembly and labelling of pre-filled glass syringes is a delicate process that must preserve the syringe and the drug it contains. Recently developed by IMA Life, MODULA is the converging element between aseptic filling and secondary packaging.

IMA SENSITIVE AP400T Labelling machine for cartons

Available as a stand-alone unit or integrated in a complete packaging line, the SENSITIVE AP400T applies tamper-evident sealing at a high speed while occupying a reduced footprint. Flexible and ergonomic, it handles a wide range of carton sizes.

IMA SENSITIVE AP400 CW Labelling machine for cartons

Compliant with the latest Track & Trace and serialization statutory requirements, the SENSITIVE AP400 CW combines an outstanding carton weighing system with a compact layout to save space in the production area.

IMA SENSITIVE 200 Labelling machine for vials and bottles

Appropriate labelling is required for all containers used for pharmaceutical drugs. The SENSITIVE 200 is a linear labelling machine suitable for applying self-adhesive labels to oval, elliptical and rectangular containers and even to cylindrical containers (one label only).

Labeling applicators

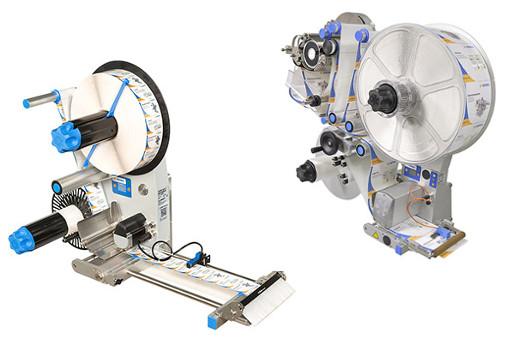

All the standard models as well as the special labeling equipment from Herma are based on the same two labeling applicators:

Herma 500 – is the flagship of Herma. Herma 500 is built in the highest quality and labels with highest precision and speed. Moreover, it is compatible with Industry 4.0 and can be combined with various printers, as well as vision and control systems.

Herma 400 – is the famous versatile labeling applicator with premium flexibility, quality, and accuracy.

Herma Basic holds many of the same skills as the H400. For more straightforward jobs it allows a more economical beneficial solution.

Herma InNo-Liner

The Herma InNo-Liner system is linerless and apply labels with the patented self-adhesive material. Due to the lack of liner and therefore the minimized waste, the Herma InNo-Liner is not only a cost-cutting game changer from the perspective of logistics and shipping, but also actively contributes to protecting the environment. In the absence of a liner, each roll can accommodate more labels, so that both the shipping weight and the necessary warehousing space are reduced.

- Lower transport volume and weight and therefore reduced CO2 emissions

- Less warehousing space

- More material on each roll and therefore fewer roll changes

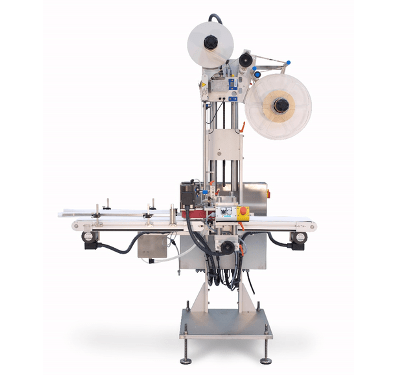

Top and bottom labeling

Top and bottom labeling is the most commonly used type of labeling. Herma and PPS offer solutions for either bottom or top labeling, or a combined fully automatic system for simultaneous application of top and bottom labels.

- Labeling speed up to 250 units per minute.

- Products are guided by either motorized side belts or special guide rails.

- Labeling system can be integrated into existing production lines.

L- and C-shape labeling

It is increasingly important to securely seal a broad range of products as well as prevent from tampering. For this, L- and C-shape labeling is ideal, as the label in general need to be applied over one or more edges. Additionally, the labels can contain an amount of variable information, such as ingredients or expiration date.

- The labeling system can easily be integrated with printing, inspection, and rejection systems.

- Labeling solutions specifically designed for the pharmaceutical and food industries.

- Compliance with the strictest requirements for tamper evident labeling.

Tabletop labeling equipment

For smaller productions, a tabletop labeling unit will be sufficient.

For these applications Herma offers a variety of solutions; from a simple unit that peels of the label from the backing paper and manual places it onto the product, to a system where the operator places a round object, e.g. a bottle, on rollers for automatic and exact labeling.

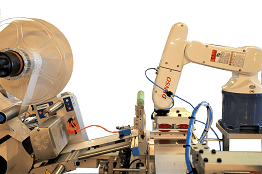

Robotic solutions for labeling

Standard labeling equipment might not be enough to solve a tricky labeling job. By combining a Herma labeling applicator and a small robot, a more flexible and/or specialized solution can be offered.

PPS designs and builds such turnkey solutions and we can supply complete lines, offering both the labeling part, but also – if needed – a packaging line for packing the labeled products into cartons, shipper boxes and onto pallets.

Explore our selection of industrial labeling machines

Together with IMA and Herma, PPS offers numerous labeling solutions designed to meet the many different needs and requirements in product and pharmaceutical labeling.

Automatic label applicators for pharmaceuticals

In the PPS selection of automatic label applicators, you will find a wide range of labelers particularly suitable for pharmaceutical labeling.

Our labelers can be configured to fit a variety of different container sizes and shapes. This makes our machines versatile as well as an excellent choice for businesses changing from manual to automatic label application.

Service & Aftersales for automatic label applicators

Uniquely for the industry, PPS has its own service department. Our service department has specially trained technicians with the highest expertise and experience surrounding industrial labeling machines. We offer a long list of services, including:

- Installation and renovation of existing labeling machines.

- Design of complete labeling solutions from the requirements, specifications and logistics to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed labeling machines and equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance of label machines as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, minimizing any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.