IMA pharmaceutical blister packaging machines

From basic small scale production to large scale integrated solutions, PPS and IMA, offer pharmaceutical blister packaging machines for your business’ specific requirements.

IMA blister packaging machines are designed with flexibility in focus, enabling these packaging machines to be tailored according to your unique production needs. Thus, the blister lines can be adapted to various products, such as tablets, capsules or ampoules.

Moreover, our pharmaceutical blister packaging machines can easily be expanded with cartoning and blister inspection and control systems.

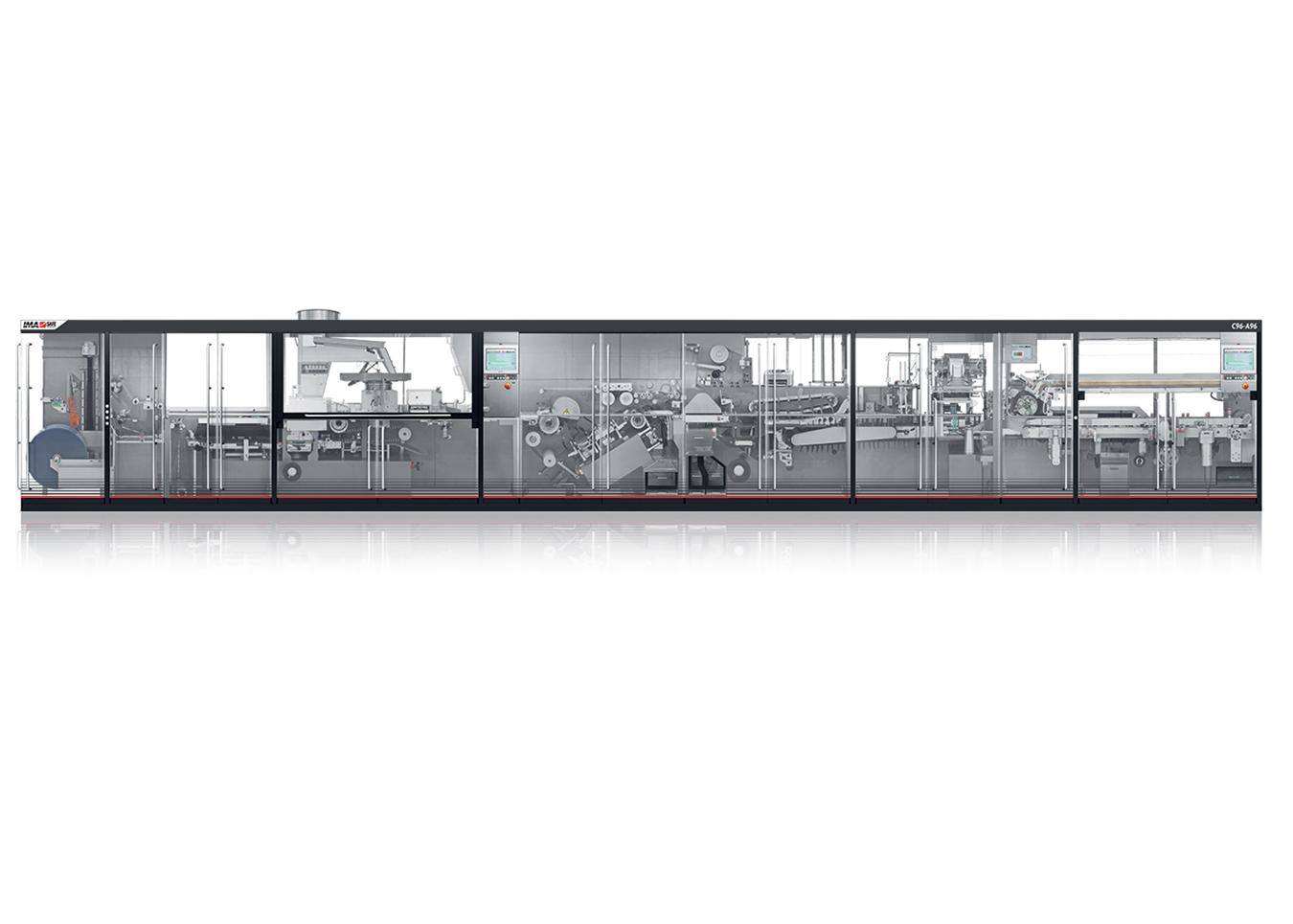

IMA C96-A96 Blister packaging machine with integrated cartoner

C96-A96 is a super high speed blister line designed specifically for those customers who need to produce large batches in a small footprint.

C96-A96 is designed with high-level technological concepts that guarantee reliability and efficiency throughout the entire packaging process. The line concept is based on continuous running, which offers big advantages in terms of product feeding efficiency and smooth running with all the packaging materials.

The high output is guaranteed also thanks to the positive blister transport which is essential for such a speed blister line. Despite the super high performance, the C96-A96 is very easy accessible and ergonomic.

- 1,300 blisters/minute in a small footprint.

- Continuous running and positive blister transfer.

- Complete accessibility and friendly using.

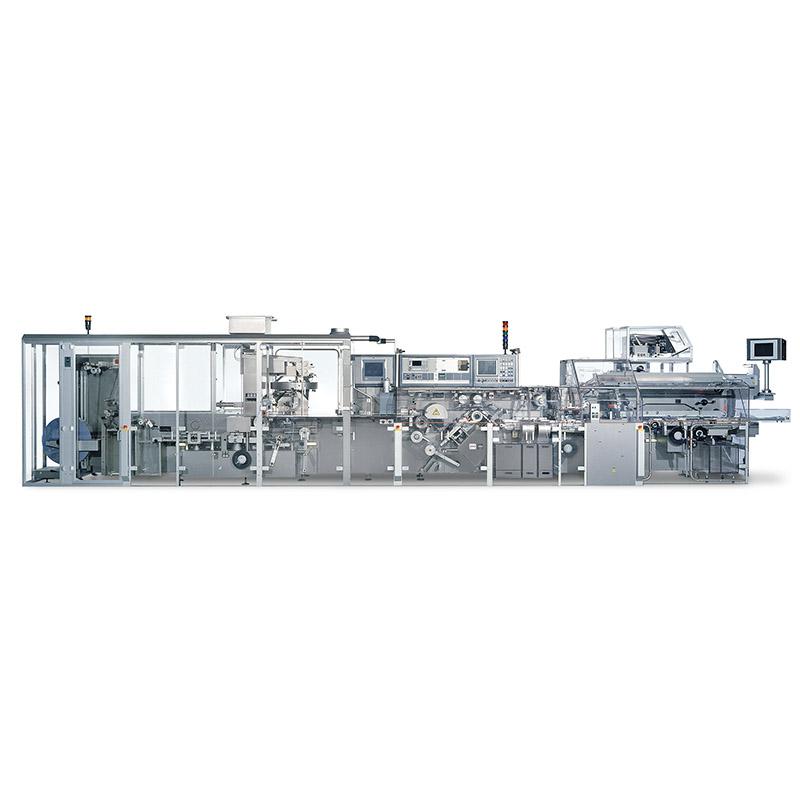

IMA C80HS Blister packaging machine with integrated cartoner

If your production requires: high productivity, maximum efficiency, state of the art technology, and a rapid return on investments, the C80HS Series is for you.

The line’s innovative design, in terms of both structure and functional detail, has been developed keeping in mind the market request. C80HS Series, double-lane blister machine, not only has high production but also has the advantage of being extremely efficient: even if the downstream machine stops the rejection is minimal thanks to the blister recovery magazine.

Last but not least, a complete accessibility in the connection area is guaranteed.

- Complete accessibility also in the connection between blister machine and cartoner.

- Modularity: possibility to integrate the C80HS with different cartoners.

- Innovative cutting unit: blister rejected with a different shape from the good one.

IMA C80 Blister packaging machine

C80R and C80-A81 are the leaders for the production of medium size batches. The high efficiency of C80-A81, thanks to the integrated connection to the cartoner, and the flexibility of C80R Stand Alone, are the key features demanded by the market.

The C80 Series offers to you the widest range in terms of applications.

Available as double-lane, three-lane in Stand Alone version, it grants high efficiency not only with the most common thermoforming materials but also with the most difficult ones, including PP and Aclar.

C80 Series is the fastest blister machine in its range giving you wide blisters, especially in Alu-Alu.

- C80-A81, characterized by a positive transport between the blister machine and the cartoner, is the ideal solution for medium size batches.

- C80R, from double-lane to three-lane production speed, is the fastest stand alone machine which is designed to be easily connected to any cartoner and wallet machine, giving the maximum flexibility in layout.

IMA GIANT Blister packaging machine

The ideal solution for just-in-time production of small-medium batches, handling any blister/product shape and configuration. With the IMA GIANT Series you choose the state of the art technology in terms of design, feeders, quality controls and servomotors.

GIANT Series grants the widest flexibility in terms of product shape, blister sizes and configurations.

An important benefit that GIANT offers to you is the IMA patented Sombrero, the most versatile and efficient universal feeder. Moreover, to satisfy all requirements for containment of solid pharmaceutical shapes in blister packaging, the feeding area is already designed for containment application.

GIANT Series is also an extremely compact line, with a unique design, able to give a linear workflow and an overall visibility of the material work to the operator.

- The feeding area is already designed for containment application.

- Complete accessibility.

- Innovative cutting unit and non-compliant blister rejection.

IMA C90-C91 Blister packaging machine with integrated cartoner

One of the first blister lines having an integrated connection from blister machine to cartoning machine through a blister positive transfer. It has been the inspiration for most of the blister lines and it’s still today a guarantee for medium speed production.

The reliability and good product quality is guaranteed by the latest quality control system. The good performances of the line, 400 blisters/minute on one row production and 270 cartons/minute, are characterized by high efficiency thanks to its consolidated technology.

- Blister positive transfer.

- Blister recovery magazine.

- Work with all packaging materials, also with the most difficult ones, including PP and Aclar.

IMA C40 Blister packaging machine

The best price-performance ratio machine in its range, the C40 Series is the answer for those customers who demand high production efficiency for small/medium batches with frequent changeovers.

The modern design of the C40 Series assures a complete visibility of the whole packaging process as well as full accessibility for the operator.

Downtimes are reduced to a minimum, thanks to easy cleaning operations and fast and simple changeovers. Moreover, the consolidated technology has a low impact on the maintenance costs.

- Best performance price ratio in its class.

- The feeding area is already designed for the containment application.

- Compact and reliable connection between blister machine and cartoner.

IMA TR200 Blister packaging machine

TR200 is a double-row blister packaging machine able to reach 350 blisters/minute. The machine is based on established technology which guarantees an excellent production reliability together with quick and easy size changeover.

350 blisters/minute in only 3.3 meters length; TR200 offers to you the highest output in the smallest footprint.

Combining high speed, extremely compact design, easy to use and low maintenance costs, IMA TR200 is the perfect machine for small/medium production batches. Size changeover times are quick due to the limited number of parts and user-friendly operations.

- 350 blisters/minute in only 3.3 meters length.

- Minimal overall dimensions (footprint).

- The widest range in terms of blister size.

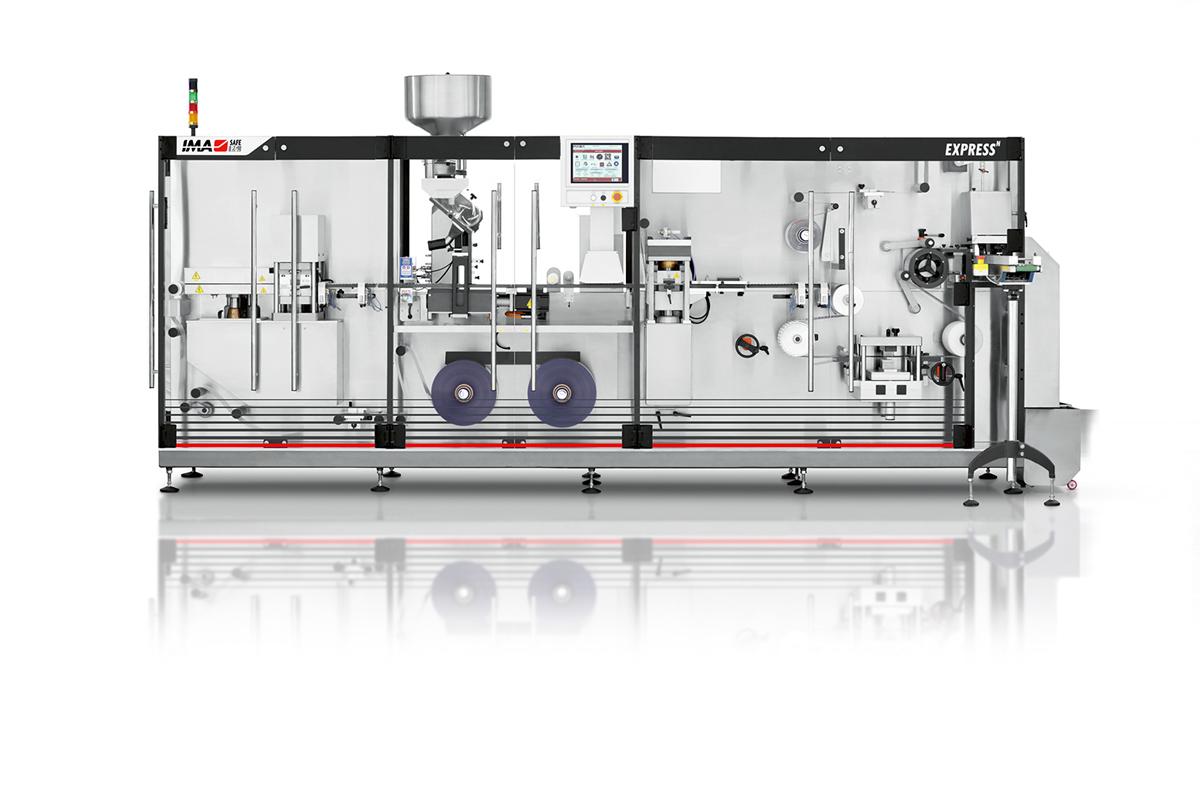

IMA EXPRESS N Blister packaging machine

EXPRESS N, produced by IMA PG, is a blister packaging machine for tablets and capsules developed for medium size production batches.

EXPRESS N is a flat forming and flat sealing blister machine able to handle thermoforming materials and aluminum. It has been developed with the IMA PG philosophy of delivering a highly efficient machine, ideal for a 24×7 production.

Each station of the machine is servo driven. EXPRESS N is also CE certified and is built as per GMP guidelines with possibility of downstream automation.

- Servo controlled operations.

- Balcony construction.

- Quick & tool-less changeover of size parts.

IMA TR135 Blister packaging machine

TR135 is a medium production speed blister packaging machine based on established technology which grants an excellent production reliability together with quick and easy changeover and operator-friendly.

The most compact machine in its production range.

The design and balcony-type structure make it extremely accessible, easy to use and allow a full view of the entire production flow. Conforming to GMP guidelines, the TR135 machine cables and other connections are housed inside the machine structure granting a fast and complete cleaning operation.

- Minimal overall dimensions (footprint).

- Very easy to operate.

- Best price/performance ratio in its category.

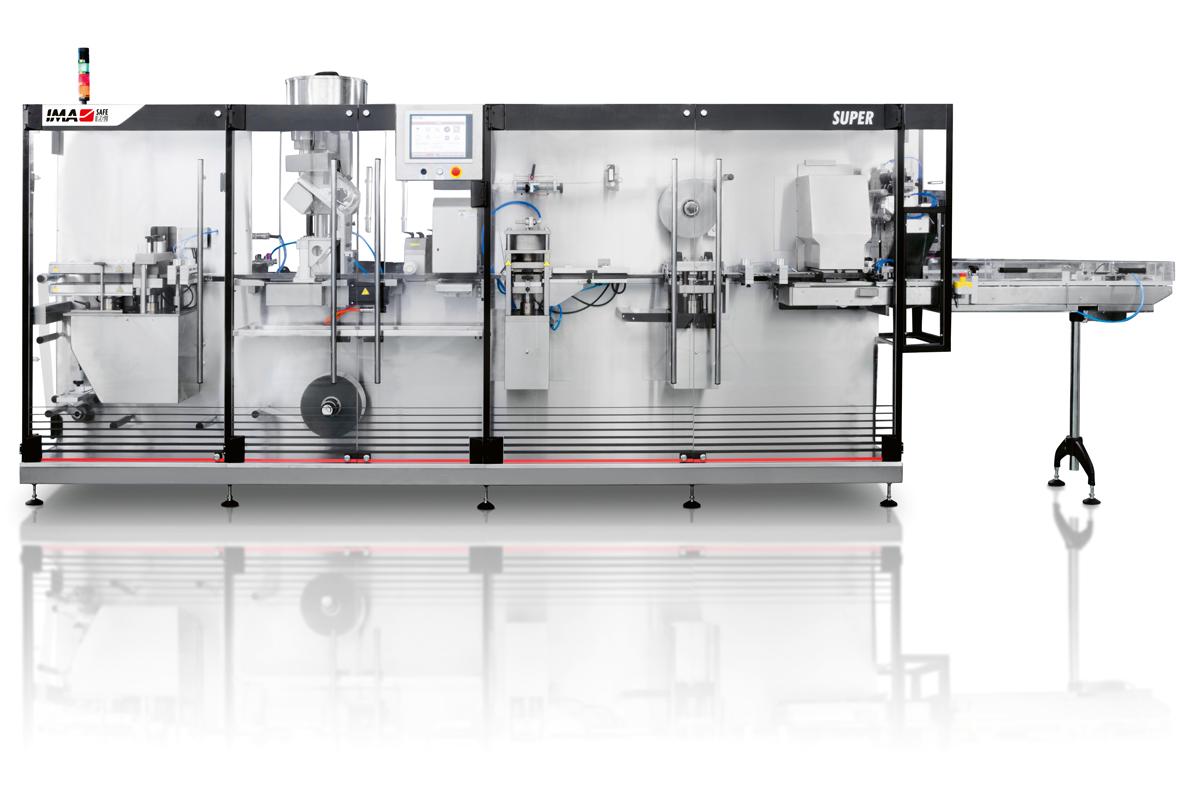

IMA SUPER Blister packaging machine

The blister machine SUPER, produced by IMA PG, is targeted for customers who need medium batches productions demanding at the same time an easy usability.

The SUPER is ideal for companies searching for a good final product obtained through a clean designed machine, very easy to use thanks to the balcony style structure. It can pack tablets, capsules and dragees, with both thermoforming material and aluminum by means of flatbed forming and intermittent motion flat sealing.

Powered by Servo technology the machine is capable of handling thermoform and cold form packaging films.

- Quick & tool-less changeover of size parts.

- Servo controlled indexing.

- Work with all forming materials.

IMA EXCEL SMART Blister packaging machine

The new blister machine EXCEL SMART, produced by IMA PG, is targeted for small-medium companies which need to place on the market a good product with a reasonable investment.

The EXCEL SMART is a low-medium speed blister packing machine with a balcony style construction. It can pack tablets, capsules and dragees, with both thermoforming material and aluminum by means of flatbed forming and intermittent motion flat sealing.

Powered by Servo technology the machine is capable of handling thermoform and cold form packaging films.

- Quick & tool-less changeover of size parts.

- Servo controlled operations.

- Balcony style construction.

IMA CLINIPACK Minimaster of the heart of the giant

The CLINIPACK is a thermoforming machine for clinical trials and short production runs. It is perfect for small size batch requirements.

The IMA CLINIPACK is a very compact economical and flexible blister machine for the packaging of tablets, capsules, dragees, ampoules, syringes and liquids. The products can be automatically fed by means of a dedicated feeder and/or manually. Last but not least, the CLINIPACK can work with all kinds of materials.

- Automatic or manual feeding.

- Flexibility of packing all products.

- Work with all materials.

Blister machines: advantages and functions of blister packaging

A blister packaging machine is a packing machine for unit dosages of pharmaceuticals. Blister cards are a common unit dosage packaging for different pharmaceutical products. They are moist and airtight, which helps to prolong the shelf life of the product.

Pharmaceutical blister packaging machines use a form-fill-seal process. In this process, the container is formed, after which the pharmaceutical product is filled in the container. Finally, the container is sealed.

The container is formed by the blister packaging machine directly from a roll of plastic wrap or other material such as PVC, PVCD, aclar, or aluminum. This is done by thermoforming or cold forming depending on the material used. For pharmaceutical products, foil or a combination of foil and paper is normally used to close and seal a blister card. The entire process takes place on the same blister line.

Blister foil and other sealing material used in blister packing

For push-through blister packs, foil is commonly used to close and seal it. Child-resistant blister cards are most often made of a mix of foil and paper. This makes it harder to push the product through the sealing.

Further, blister cards can be made from cold formed aluminum-aluminum (alu-alu). Alu-alu is the only blister packaging that provides 100% protection against moisture, air and light. Therefore, it typically applies to extra sensitive products. Moreover, blister foil helps to ensure the integrity of the product, as any breakage of the foil will be clearly visible.

IMA pharmaceutical blister packing machines can process several different types of sealing material. This includes common types of thermoforming films, cold forming films and film for alu-alu blister cards.

Complete blister packaging line

By combining IMA blister packaging machines with Promatic cartoning solution, PPS and IMA offer a complete blister packing line. Each blister line can be configured according to individual needs. An example of a complete blister line includes:

- Pharmaceutical blister packaging machine

- Blister inspection system

- Cartoning machine; including box folding, feeding of information leaflets and blister cards, as well as printing and marking the boxes

- Shrink foil unit

- Palletizing equipment

For more information about any type of blister solution, please contact us directly. You might also want to learn more about our different packaging options.

Pharmaceutical blister packaging machines: service & aftersales

Uniquely for the industry, PPS has its own service department that is directly available to our customers. Our specially trained technicians possess the highest level of expertise and experience concerning pharmaceutical blister packaging machines. We offer a long list of services, including:

- Installation, renovation or moving of existing blister packing equipment and entire production or packaging lines.

- Competent feedback on automation solutions or other types of production optimization

- Training of technical personnel and operators in optimal use of blister packing machines.

- Tailor-made service and aftersales agreements for ongoing maintenance of packaging machines for pharmaceuticals as well as assistance in case of breakdown

- Direct delivery of spare parts and consumables to our customers from our own stock, minimizing production downtime

IMA pharmaceutical blister packaging machines

From basic small scale production to large scale integrated solutions, PPS and IMA, offer pharmaceutical blister packaging machines for your business’ specific requirements.

IMA blister packaging machines are designed with flexibility in focus, enabling these packaging machines to be tailored according to your unique production needs. Thus, the blister lines can be adapted to various products, such as tablets, capsules or ampoules.

Moreover, our pharmaceutical blister packaging machines can easily be expanded with cartoning and blister inspection and control systems.

IMA C96-A96 Blister packaging machine with integrated cartoner

C96-A96 is a super high speed blister line designed specifically for those customers who need to produce large batches in a small footprint.

C96-A96 is designed with high-level technological concepts that guarantee reliability and efficiency throughout the entire packaging process. The line concept is based on continuous running, which offers big advantages in terms of product feeding efficiency and smooth running with all the packaging materials.

The high output is guaranteed also thanks to the positive blister transport which is essential for such a speed blister line. Despite the super high performance, the C96-A96 is very easy accessible and ergonomic.

- 1,300 blisters/minute in a small footprint.

- Continuous running and positive blister transfer.

- Complete accessibility and friendly using.

IMA C80HS Blister packaging machine with integrated cartoner

If your production requires: high productivity, maximum efficiency, state of the art technology, and a rapid return on investments, the C80HS Series is for you.

The line’s innovative design, in terms of both structure and functional detail, has been developed keeping in mind the market request. C80HS Series, double-lane blister machine, not only has high production but also has the advantage of being extremely efficient: even if the downstream machine stops the rejection is minimal thanks to the blister recovery magazine.

Last but not least, a complete accessibility in the connection area is guaranteed.

- Complete accessibility also in the connection between blister machine and cartoner.

- Modularity: possibility to integrate the C80HS with different cartoners.

- Innovative cutting unit: blister rejected with a different shape from the good one.

IMA C80 Blister packaging machine

C80R and C80-A81 are the leaders for the production of medium size batches. The high efficiency of C80-A81, thanks to the integrated connection to the cartoner, and the flexibility of C80R Stand Alone, are the key features demanded by the market.

The C80 Series offers to you the widest range in terms of applications.

Available as double-lane, three-lane in Stand Alone version, it grants high efficiency not only with the most common thermoforming materials but also with the most difficult ones, including PP and Aclar.

C80 Series is the fastest blister machine in its range giving you wide blisters, especially in Alu-Alu.

- C80-A81, characterized by a positive transport between the blister machine and the cartoner, is the ideal solution for medium size batches.

- C80R, from double-lane to three-lane production speed, is the fastest stand alone machine which is designed to be easily connected to any cartoner and wallet machine, giving the maximum flexibility in layout.

IMA GIANT Blister packaging machine

The ideal solution for just-in-time production of small-medium batches, handling any blister/product shape and configuration. With the IMA GIANT Series you choose the state of the art technology in terms of design, feeders, quality controls and servomotors.

GIANT Series grants the widest flexibility in terms of product shape, blister sizes and configurations.

An important benefit that GIANT offers to you is the IMA patented Sombrero, the most versatile and efficient universal feeder. Moreover, to satisfy all requirements for containment of solid pharmaceutical shapes in blister packaging, the feeding area is already designed for containment application.

GIANT Series is also an extremely compact line, with a unique design, able to give a linear workflow and an overall visibility of the material work to the operator.

- The feeding area is already designed for containment application.

- Complete accessibility.

- Innovative cutting unit and non-compliant blister rejection.

IMA C90-C91 Blister packaging machine with integrated cartoner

One of the first blister lines having an integrated connection from blister machine to cartoning machine through a blister positive transfer. It has been the inspiration for most of the blister lines and it’s still today a guarantee for medium speed production.

The reliability and good product quality is guaranteed by the latest quality control system. The good performances of the line, 400 blisters/minute on one row production and 270 cartons/minute, are characterized by high efficiency thanks to its consolidated technology.

- Blister positive transfer.

- Blister recovery magazine.

- Work with all packaging materials, also with the most difficult ones, including PP and Aclar.

IMA C40 Blister packaging machine

The best price-performance ratio machine in its range, the C40 Series is the answer for those customers who demand high production efficiency for small/medium batches with frequent changeovers.

IMA TR200 Blister packaging machine

TR200 is a double-row blister packaging machine able to reach 350 blisters/minute. The machine is based on established technology which guarantees an excellent production reliability together with quick and easy size changeover.

IMA EXPRESS N Blister packaging machine

EXPRESS N, produced by IMA PG, is a blister packaging machine for tablets and capsules developed for medium size production batches.

IMA TR135 Blister packaging machine

TR135 is a medium production speed blister packaging machine based on established technology which grants an excellent production reliability together with quick and easy changeover and operator-friendly.

IMA SUPER Blister packaging machine

The blister machine SUPER, produced by IMA PG, is targeted for that customers who need medium batches productions demanding at the same time an easy usability.

The SUPER is ideal for that companies searching for a good final product obtained though a clean designed machine, very easy to use thanks to the balcony style structure. It can pack tablets, capsules and dragees, with both thermoforming material and aluminum by means of flatbed forming and intermittent motion flat sealing.

Powered by Servo technology the machine is capable of handling thermoform and cold form packaging films.

IMA EXCEL SMART Blister packaging machine

The new blister machine EXCEL SMART, produced by IMA PG, is targeted for small-medium companies which need to place on the market a good product with a reasonable investment.

IMA CLINIPACK Minimaster of the heart of the giant

The CLINIPACK is a thermoforming machine for clinical trials and short production runs. It is perfect for small size batch requirements.

Blister machines: advantages and functions of blister packaging

A blister packaging machine is a packing machine for unit dosages of pharmaceuticals. Blister cards are a common unit dosage packaging for different pharmaceutical products. They are moist and airtight, which helps to prolong the shelf life of the product.

Pharmaceutical blister packaging machines use a form-fill-seal process. In this process, the container is formed, after which the pharmaceutical product is filled in the container. Finally, the container is sealed.

The container is formed by the blister packaging machine directly from a roll of plastic wrap or other material such as PVC, PVCD, aclar, or aluminum. This is done by thermoforming or cold forming depending on the material used. For pharmaceutical products, foil or a combination of foil and paper is normally used to close and seal a blister card. The entire process takes place on the same blister line.

Blister foil and other sealing material used in blister packing

For push-through blister packs, foil is commonly used to close and seal it. Child-resistant blister cards are most often made of a mix of foil and paper. This makes it harder to push the product through the sealing.

Further, blister cards can be made from cold formed aluminum-aluminum (alu-alu). Alu-alu is the only blister packaging that provides 100% protection against moisture, air and light. Therefore, it typically applies to extra sensitive products. Moreover, blister foil helps to ensure the integrity of the product, as any breakage of the foil will be clearly visible.

Noack pharmaceutical blister packing machines can process several different types of sealing material. This includes common types of thermoforming films, cold forming films and film for alu-alu blister cards.

Complete blister packaging line

By combining Noack blister packaging machines with Promatic cartoning solution, PPS and Romaco offer a complete blister packing line. Each blister line can be configured according to individual needs. An example of a complete blister line includes:

- Pharmaceutical blister packaging machine

- Blister inspection system

- Cartoning machine; including box folding, feeding of information leaflets and blister cards, as well as printing and marking the boxes

- Shrink foil unit

- Palletizing equipment

For more information about any type of blister solution, please contact us directly. You might also want to learn more about our different packaging options.

Pharmaceutical blister packaging machines: service & aftersales

Uniquely for the industry, PPS has its own service department that is directly available to our customers. Our specially trained technicians possess the highest level of expertise and experience concerning pharmaceutical blister packaging machines. We offer a long list of services, including:

- Installation, renovation or moving of existing blister packing equipment and entire production or packaging lines.

- Competent feedback on automation solutions or other types of production optimization

- Training of technical personnel and operators in optimal use of blister packing machines.

- Tailor-made service and aftersales agreements for ongoing maintenance of packaging machines for pharmaceuticals as well as assistance in case of breakdown

- Direct delivery of spare parts and consumables to our customers from our own stock, minimizing production downtime