IMA liquid process equipment

Together with IMA, PPS delivers advanced liquid process equipment for the pharmaceutical industry, including solutions for handling aseptic and toxic liquids.

IMA solutions are high quality equipment designed and built with high-tech components according to cGMP and GEP regulations.

Liquid process equipment can be delivered as individual pieces of equipment, a mobile unit or even complete integrated production plants. We can also provide equipment for heating, cooling, and homogenisation.

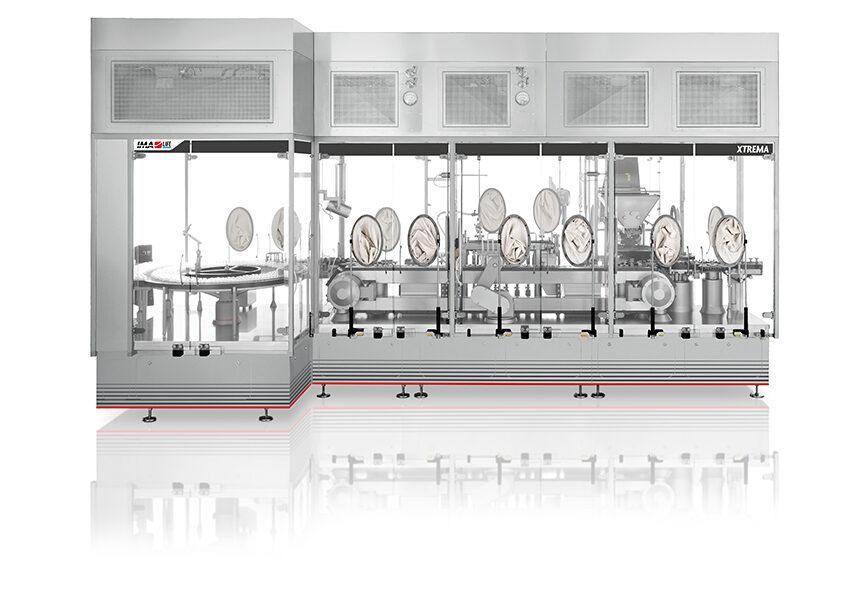

IMA XTREMA High speed filling & stoppering machine

The main concern of the pharmaceutical packaging market has always been the integrity of the drug, and, in the case of parenteral dosage forms, its sterility. XTREMA indeed embodies the latest technological breakthrough in aseptic filling.

During the aseptic filling of dose containers with a drug, essential is preventing its contamination, thus minimizing its exposure to environment, equipment, manipulation from operators, etc., until it’s sealing.

XTREMA fundamental characteristics respond to the industry’s stringent technical requirements of vial filling, and with its flexible and ergonomic design it assures the most complete possibility to integrate modular equipment, and, why not, even to install multiple filling systems (liquids & powders) to be used alternatively within the same machine frame.

- Ergonomic displacement of operating groups

- Geometry facilitating the unidirectional air flow (UAF)

- Ideal to be exposed to VHP (Hydrogen Peroxide in Vapour Phase)

IMA LYNFINITY Continuos aseptic spray-freeze-drying

Raising productivity and reducing downtime is now possible in a continuous aseptic process, with constant monitoring from fermentation to final packaging.

LYnfinity spray-freeze-drying process features a controlled spray of liquid product into a cryogenically cooled freezing chamber. The resultant frozen particles of the liquid product are freeze-dried in the drying module. The drying chamber contents are both transported and heated to promote rapid sublimation and prevent agglomeration.

The continuous spray-freeze-drying process starts with bulk liquid product and ends with the discharge of dried particles, featuring total containment from formulation to powder filling. This enables higher sterility assurance levels, whereas traditional freeze-drying requires additional external material handling, for example during filling. Upon completion of drying, the uniform, dried spherical product allows for the use of a variety of containers (vials, syringes, inhalation systems etc.).

- Designed for continuous process from fermentation to final packaging

- Greater throughput flexibility: minimization of scale up and scale down challenges

- Better quality attributes: improved product uniformity through a gentle drying process

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.